Marine growth prevention systems for seawater pipework

Electrotest Marine – your total solutions provider for the installation and repair of MGPS systems

Marine growth prevention systems have proved to be an effective and reliable method of mitigating blockages caused by bio-fouling. Without anti-fouling protection, pipes become encrusted with macro fouling leading to partial or total blockages which reduces the efficiency of the seawater cooling system which could lead to engine shutdown.

- Based on the electrolytic principle, providing continuous and reliable protection without the use of chemicals.

- Major savings in pipework maintenance costs throughout the life of the vessel.

- Consists of a control panel and copper and aluminium (or ferrous) anodes installed in sea chests or strainers, wired to the control panel.

- Copper ions prevent micro and macro fouling from settling in the pipework.

- Aluminium or ferrous ions help mitigate certain types of corrosion on the internal surfaces of the pipework.

- Concentrations of ions are around 2 parts per billion – environmentally benign with no effect on wider marine environment.

- Every system custom designed for its particular application.

- Easy installation – anodes can be installed in sea chests or strainers at new build stage or retrofit.

- Approved by classification societies.

- Anodes and control panels are available for all types of vessels ranging from cruise and commercial ships to workboats and superyachts.

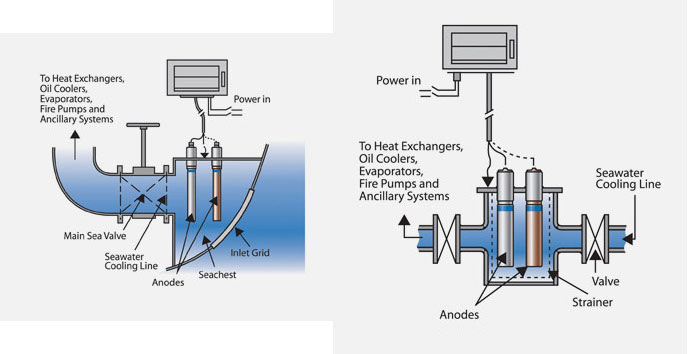

Sea chest or strainer mounted anodes

When systems are installed at newbuilding, anodes are generally fitted in the sea chests using special sleeves or flanged mountings.

Alternatively, if systems need to be installed prior to scheduled dry docking, the anodes can be mounted in the seawater strainers. This also simplifies replacement when anode renewal becomes necessary.

In special cases, where the system supersedes existing chemical based anti-fouling equipment, the anodes can be mounted in treatment (electrolysis) tanks in order to economise on the installation costs by utilising existing pipework.

Sea chest anodes & Strainer mounted anodes